Instructor

Description

Overview

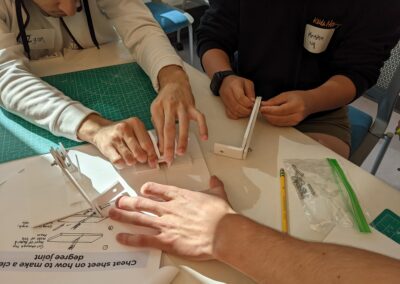

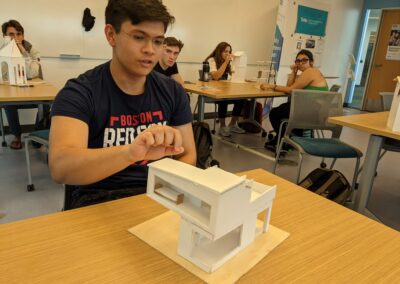

Introduction to Making is an exploratory course that gives you the practical, hands-on skills to make working prototypes of your products. You will learn to make physical things, make them work, and integrate them with electronics/software. Common fabrication techniques including foamboard, 3D printing, laser cutting, electronics, and Arduino programming. You will be demonstrating your hands-on skills as well as your entrepreneurial spirit in a final project.

Learning Outcomes

Upon completion, students will:

- Know that they can harness technology themselves through hands-on making without fear or prior physical making and coding knowledge

- Have developed confidence and proficiency in maker tools and techniques, such as concept drawing, hand modeling, 3d printing, laser cutting, electronics, and working with connected devices

- Know how to collaborate in multidisciplinary teams to design and build working prototypes

- Have acquired an entrepreneurial mindset by learning to apply the “build-measure-learn” loop through failing fast and doing rapid iterations

Course Topics and Objectives

- Develop Foundation Skills: Master the idea-to-prototype process through hands-on making, team formation, the entrepreneurial mindset of “build-measure-learn”, and navigating maker spaces with proper safety protocols.

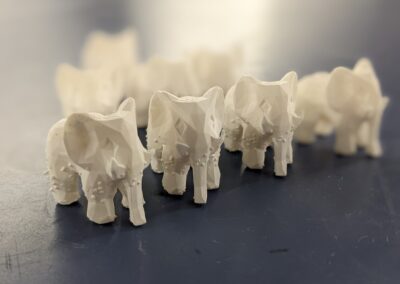

- Learn To Do Digital Fabrication: Design and fabricate physical objects using CAD software, laser cutters for 2D projects, and 3D printers for complex geometries.

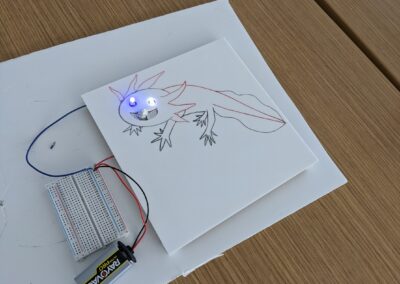

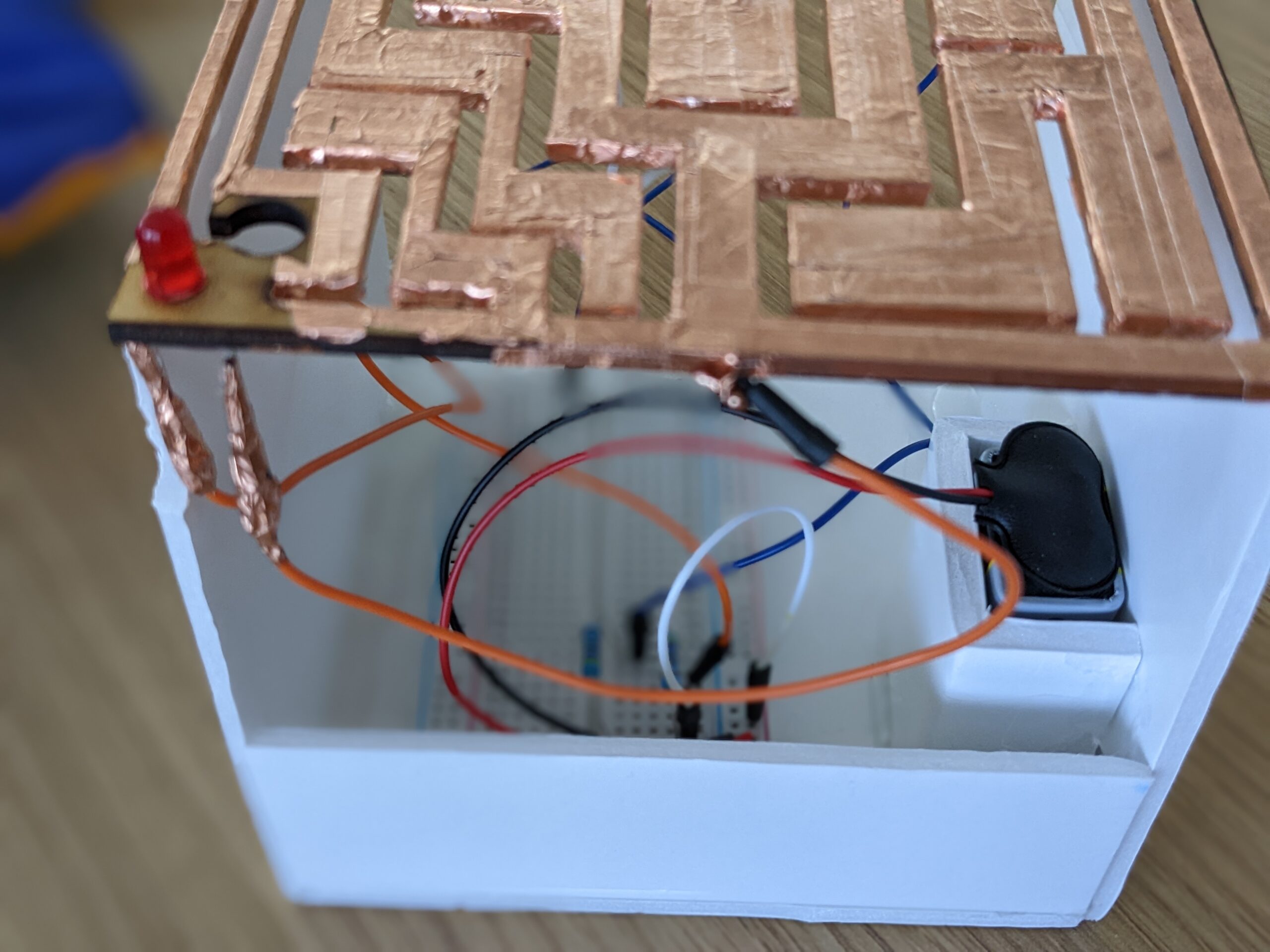

- Acquire skills in Electronics and Programming: Build functional circuits with electronic components and program microcontrollers using MicroPython, enhanced by AI-assisted code generation.

- Learn to design and develop connected devices: Create smart IoT devices that sense environmental data, visualize information, and enable remote monitoring and control through web interfaces.

- Understand the unique challenges and rewards for hardware startups: Apply hardware startup principles to iterate prototypes from v0 to v1, culminating in a showcase that demonstrates market-ready functionality.

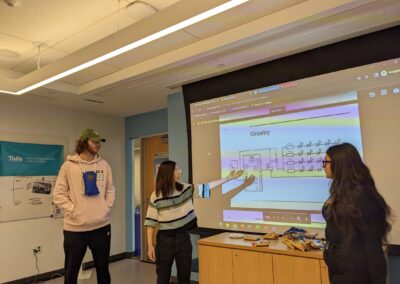

- Collaborative Innovation: Work effectively in multidisciplinary teams to leverage diverse skills, resolve technical challenges collectively, and integrate different perspectives into cohesive prototype solutions.

What people say

“This course gave me the opportunity to try something new, such as coding, connectivity and using electronics. It was a good learning experience to actually build something by hand.”

– An ENT164 Student

“As an Entrepreneurship minor, I originally took this course to complete my minor requirements. I quickly realized that the material we would be covering (computer science/coding, CAD, connectivity, prototype design, etc.) was completely new to me. However, I am very thankful I decided to stick with this course because it offered a taste of all of the work that goes into designing and creating products for user function.”

– An ENT164 Student